The cool thing about a project like this is that it encompasses so many different disciplines. I'm mainly a mechanical guy, but I'm getting to learn a lot about autopilots and navigation and Arduino.

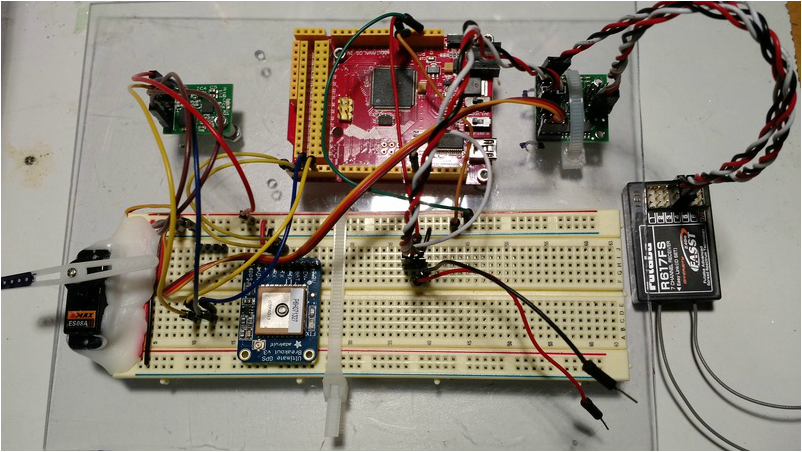

Here you see the beginnings of Seacharger's autopilot. Clockwise from the upper left: tilt-compensated compass (Devantech CMPS-11), Seeeduino Mega (basically an Arduino Mega in a slightly smaller form factor), servo mux board from Pololu, R/C receiver, Adafruit GPS, and a servo. Special thanks to JT for putting together all these components and getting them to talk to each other!

After reading about Arduino code and making a mockup of the autopilot in Excel, I managed to get a pretty decent autopilot working. What I mean by this is that I could program in some waypoints and then take this setup to a local park and have it guide me to the waypoints by moving the servo arm in the direction it wanted me to walk. There were a lot of bugs in the code, mainly having to do with passing from 359 degrees heading to 0 degrees heading or from 180 degrees to -180 degrees. But I got all those worked out and it's all good now. This kind of work is really fun because you can make progress so quickly. Those software guys have it easy!

Here you see the beginnings of Seacharger's autopilot. Clockwise from the upper left: tilt-compensated compass (Devantech CMPS-11), Seeeduino Mega (basically an Arduino Mega in a slightly smaller form factor), servo mux board from Pololu, R/C receiver, Adafruit GPS, and a servo. Special thanks to JT for putting together all these components and getting them to talk to each other!

After reading about Arduino code and making a mockup of the autopilot in Excel, I managed to get a pretty decent autopilot working. What I mean by this is that I could program in some waypoints and then take this setup to a local park and have it guide me to the waypoints by moving the servo arm in the direction it wanted me to walk. There were a lot of bugs in the code, mainly having to do with passing from 359 degrees heading to 0 degrees heading or from 180 degrees to -180 degrees. But I got all those worked out and it's all good now. This kind of work is really fun because you can make progress so quickly. Those software guys have it easy!

RSS Feed

RSS Feed