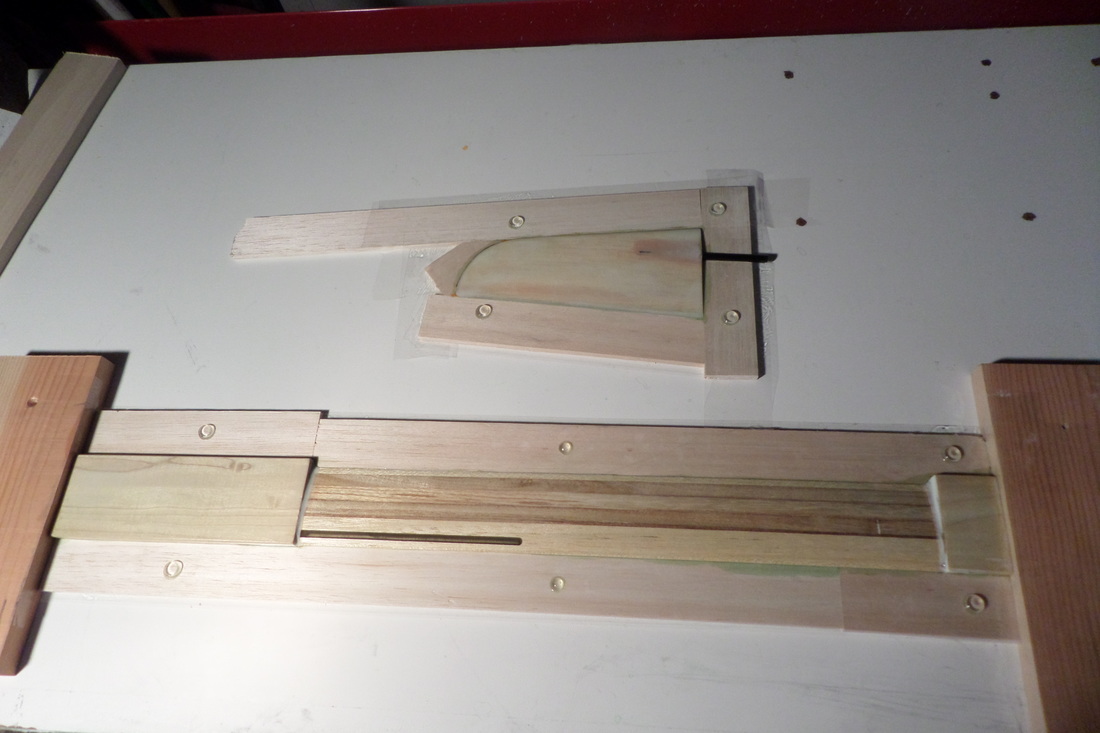

First I took the plugs and surrounded them with material to put the mold parting line at the right place. Notice also the little clear plastic stick-on drawer bumpers. They will make perfect keying features in the molds.

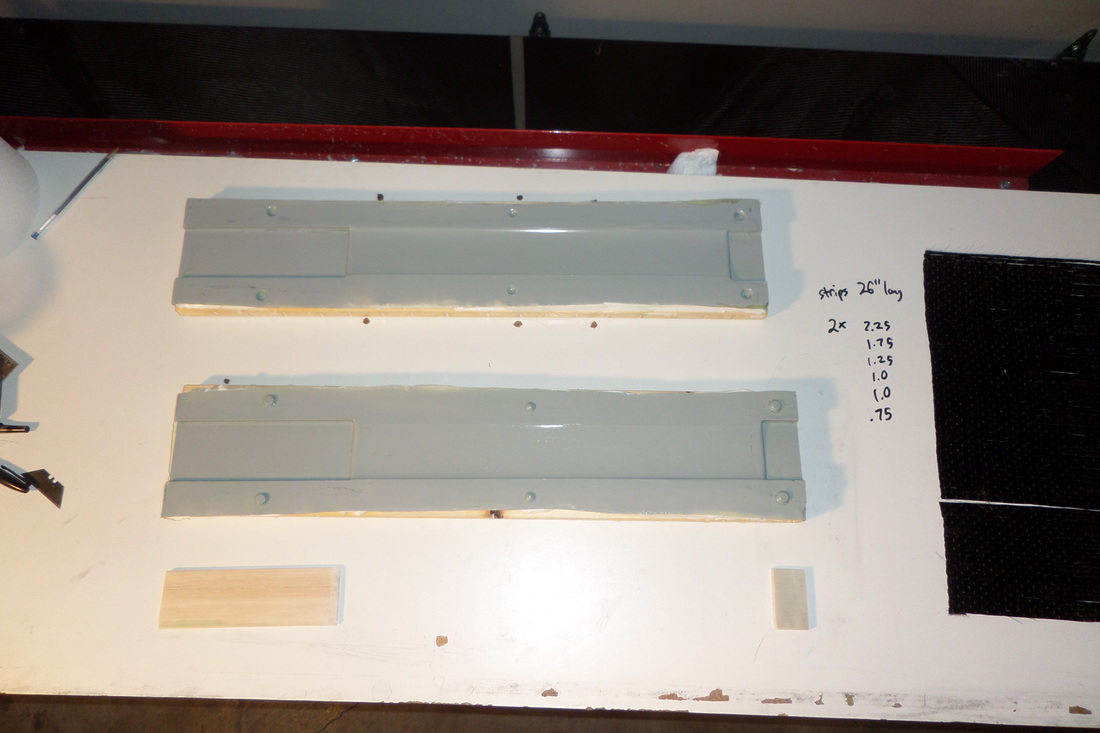

With the molds ready, I had to decide how much carbon I was going to squeeze into the molds. I aimed to fill the airfoil section of the struts 80% full with carbon. In other words, I calculated the cross-sectional area of the airfoil section, multiplied by 0.8, then divided by the thickness of the carbon fiber to get the total width of carbon fiber. Then I did a test-fit of that much carbon fiber to see if I could get it all into the mold. Well, surprise surprise, no luck. I ended up getting only 60% or so in there.

I wetted out the carbon with epoxy, cut it into strips of various widths, and laid half of them in one mold half and half in the other. The first layer was actually a layer of bidirectional carbon cloth, but then everything else was unidirectional.

RSS Feed

RSS Feed